SINTEF writes in their report, Reuse of building materials - Market, drivers and barriers, about increasing interest for reuse among architects and consultants. "For the consulting communities, the interest is broad and includes consulting engineers, interior architects and landscape architects."

Head of Research at SINTEF, Petra Rüther, tells Fremtidens Byggenæring (The Construction Industry of the Future) that they do a lot of research on developing better and more sustainable building materials.

"The best thing is still to use more of what we already have over again."

What are Sustainable Materials and How are Resources Best Utilized?

Sustainable building materials are a relatively broad concept, but work is constantly being done to create products that are better for the environment. According to Rüther, to a certain extent, industries are thinking in "silos". This means that we're not finding the best solutions across industries as efficiently.

SINTEF does a lot of research on concrete, how to make it more environmentally friendly, and on using building materials as sensibly as possible.

Although research is being done on the development of environmentally friendly building materials, the greatest need in the mining industry is smarter solutions for reuse and recycling.

Particularly large players who own a lot of buildings have increased focus on this, but there is generally a lot of interest in this in the market.

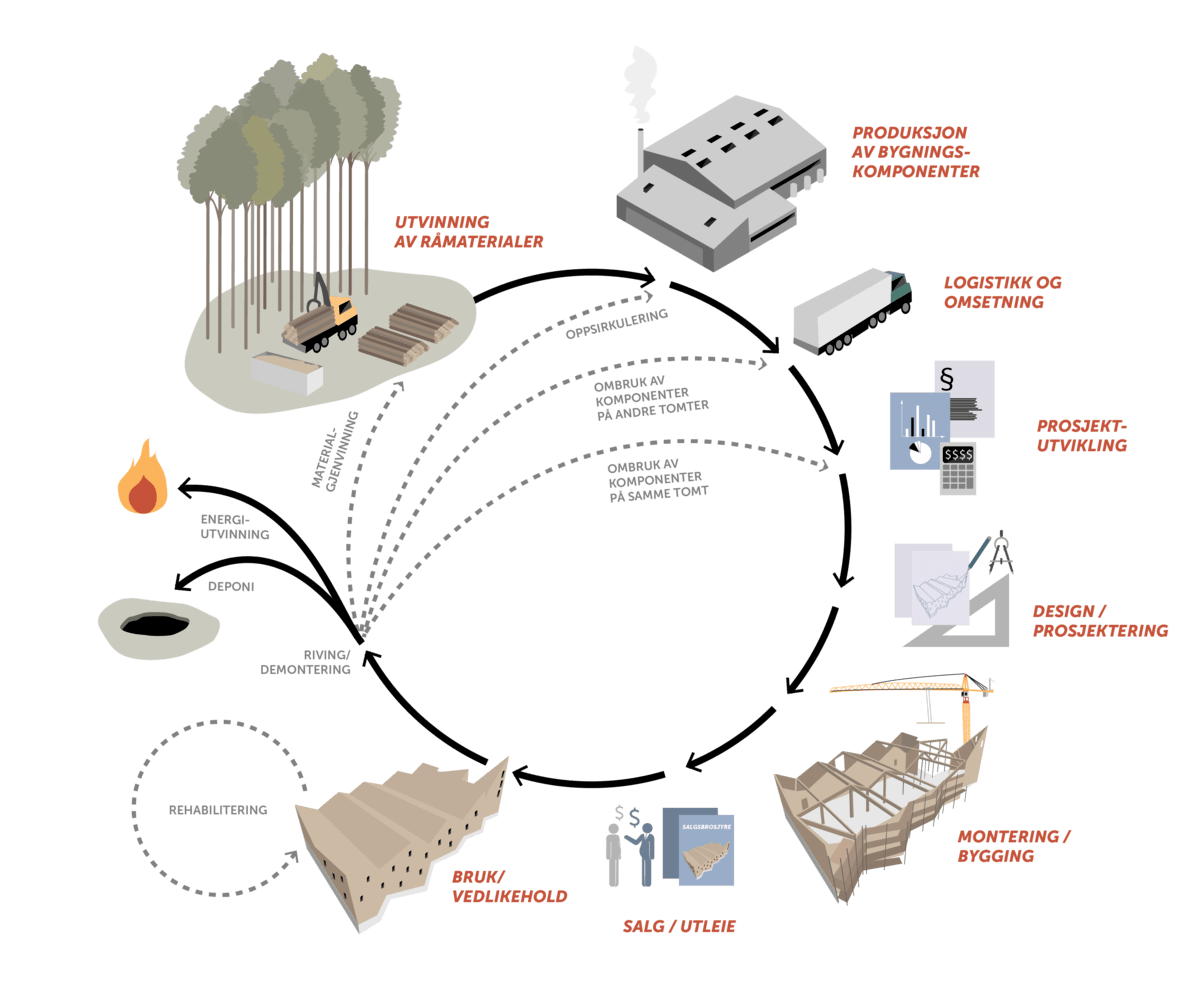

All in all, it is about the lifespan of materials, and the circular economy is therefore essential. It is important to make materials that last as long as possible. The materials must, of course, be of good quality so that it "does not fall apart halfway into the expected life. However, it is also important that we do not produce things that must be disposed of because we cannot reuse it when the product is discarded and outdated", says Rüther .

Builders should also not take shortcuts where they only think short-term profit. One must create a culture where quality and long-term thinking is at the heart of the construction industry - both to save the environment and money in the long run.

Danish architectural firms such as Lendager Group and Tegnestuen Vandkunsten are gaining great international recognition due to implementing reuse in many of their projects. The former has created Upcycle Studios, which focuses exclusively on developing models for the reuse of building components.

In Norway, on the other hand, large-scale reuse of building components has been almost forgotten in recent decades. There are, with some exceptions in the experimental marginal zone of architecture, and with new projects such as the rebuilt "Kristian Augusts gate 13" and using digital tools that enable mapping, documentation, interaction , logistics and reporting, reuse of building components is on its way up in Norway as well.

Source: Asplan Viak

Documentation is Crucial for Reuse

Manufacturers must, to a greater and greater extent, be able to document where all raw materials come from. In addition, you will have to present what is intended to happen to the building materials when they need to be replaced.

National and international requirements will contribute to increased accountability from the players in the industry.

With good documentation of the materials used, it will be possible to streamline new concepts in the circular economy. Rentals, reuse, dismantling, surveying, transport, storage and marketplaces for used materials are just a few examples of this.

Plans for reuse should start early in a project. Circular surveying of donor buildings or surveying of inventory will constitute a much larger part of the total planning of construction projects in the future than it has done so far.

"If you as a business owner can not document sustainability, you will lose opportunities in the market" - Head of Research SINTEF, Petra Rüther

SINTEF writes in their report, Reuse of building materials - Market, drivers and barriers, that «Technology companies offer solutions for sales, storage and dismantling services for consumables and develop surveying tools that allow you to keep track of the materials found in buildings. The start-up company Loopfront has developed a platform that handles surveying, documentation, collaboration, logistics and reporting for reuse of building materials and inventory. "

Reuse has an advantage over climate-friendly materials

The report from Enova and Asplan Viak, «Climate-friendly building materials», states that reuse has an advantage over climate-friendly material use

This is because it is actually a direct socio-economic gain at the other end, where you can save large amounts of resources by reusing more.

Ombruk av bygningskomponenter har imidlertid større regulatoriske utfordringer enn bruk av nye klimavennlige materialer, da dagens regelverk knyttet til omsetning og bruk av byggevarer ikke er tilpasset ombruk. Loopfront gjør dette enklere ved å kunne dokumentere all nødvendig informasjon for å implementere ombruk i praksis.

Reuse of building components, however, has greater regulatory challenges than the use of new climate-friendly materials, as current regulations related to the sale and use of building materials are not adapted to reuse. Loopfront makes this easier by enabling documentation of all the necessary information to implement reuse in practice.

Does your company want to try circular surveying? Book a call with an expert!

Related Posts

How to map used building materials!

During this year, several municipalities and organizations in Scandinavia have mapped over 30,000 ...

Circular economy platform Loopfront raises $6m USD

Loopfront – the digital circular management platform for business and government – announces an ...

Tips: Create value from your reuse survey

Both Swedish and Norwegian legislation require that buildings facing demolition or major rebuilding ...