Worn out artificial turf pitches have become one of the biggest unaddressed environmental problems of our time. According to forskning.no, almost three quarters of the microplastic in Norway comes from car tires, either as tire wear on the roads or from granules on artificial turf pitches. As much as 1,600 tonnes of Norway's annual emissions of microplastics come from artificial turf pitches alone. As the first in the world, Tebe Sport offers a sustainable and cost-effective solution for the disposal and separation of artificial turf and associated contaminated masses. We spoke with the chairman of the board, Lars Solberg, in TeBe Sport.

Can you really recycle all types of artificial turf pitches?

I Norge er det ganske lik opbygning på gressbaner. Dette gjør at vi enkelt kan resirkulere og gjenbruke alle banene på samme måte. Ved gjenbruk og resirkulering separeres innfyllet fra kunstgressmatten, og alle komponentene renses, tørkes og pakkes i “big-bags” og det tomme gresset rulles opp i ruller. Etter bearbeidingsprosessen er de ulike rene, separerte fraksjonene igjen blitt råvarer som kan brukes på eksisterende eller nye idrettsanlegg. De kan også resirkuleres for industriell produksjon av plast-, gummi- eller andre sandbaserte produkter.

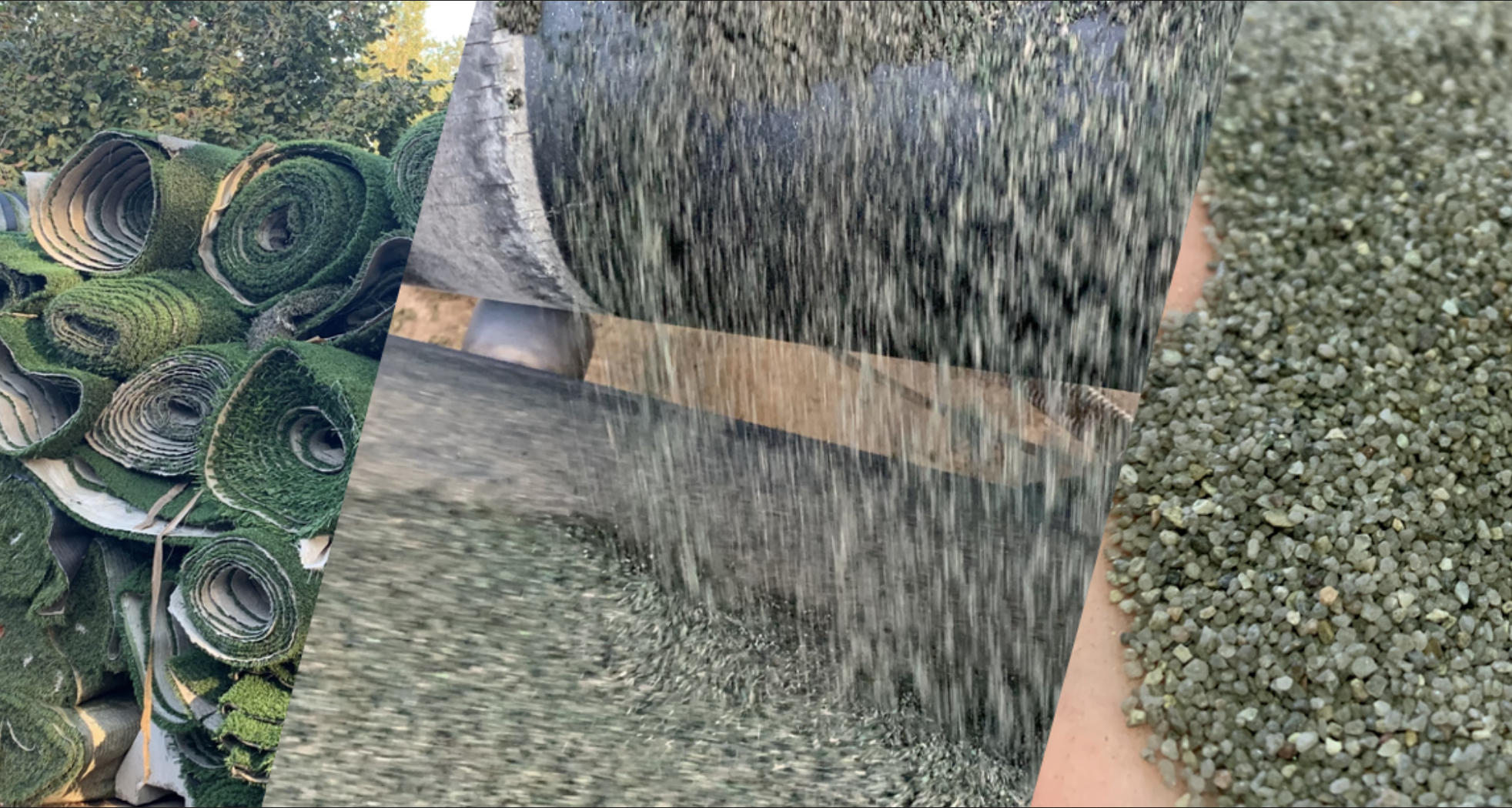

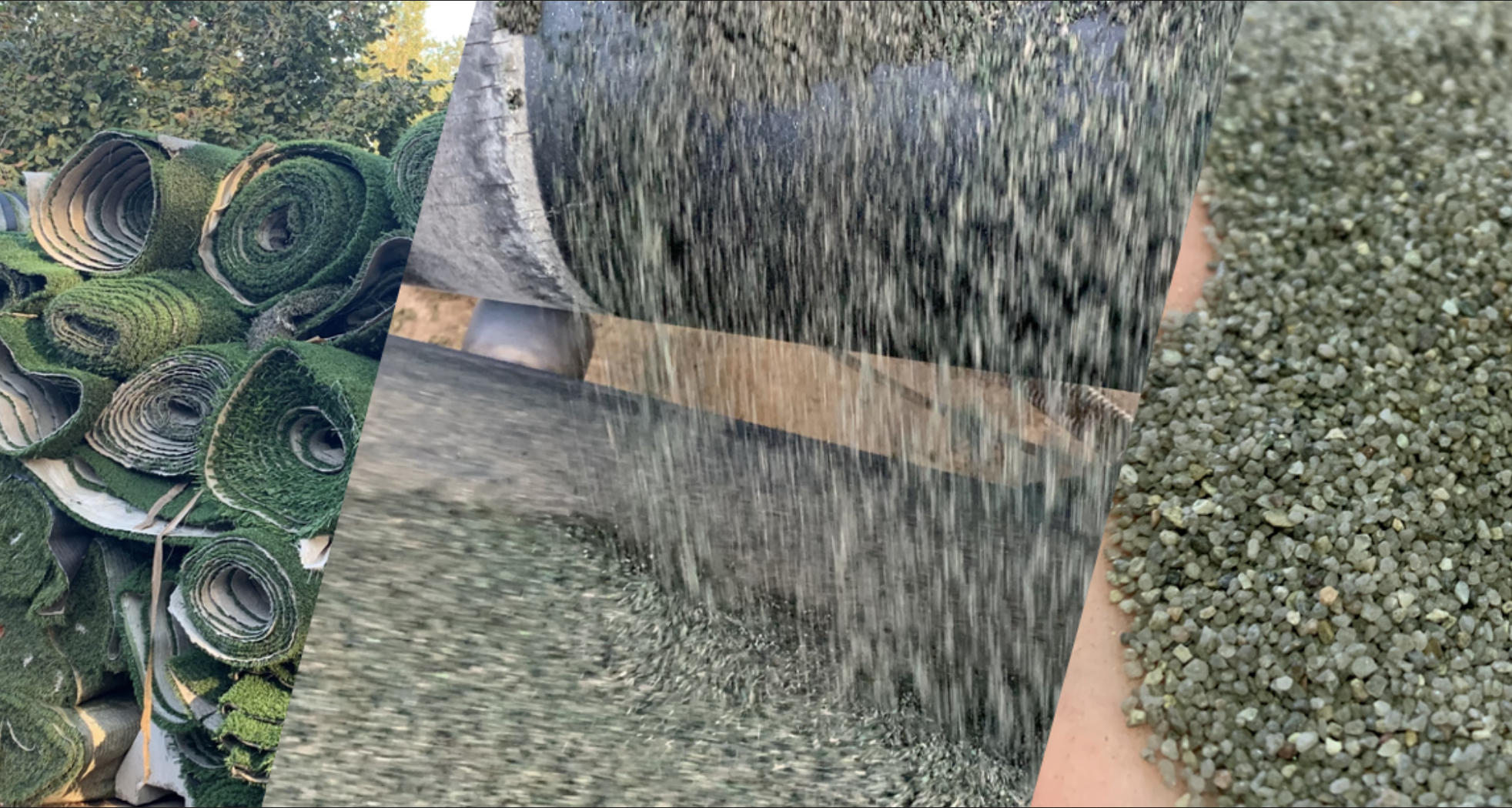

In Norway, there is quite a similar structure on artificial grass pitches. This allows us to easily recycle and reuse all the pitches in the same way. For reuse and recycling, the infill is separated from the artificial turf, and all components are cleaned, dried and packed in “big-bags” and the empty grass is rolled up into rolls. After the processing process, the various clean, separated fractions have again become raw materials that can be used on existing or new sports facilities. They can also be recycled for industrial production of plastic, rubber or other sand-based products.

Kilde: Tebe Sport

How much can an artificial turf pitch save in terms of emissions?

One normal large football pitch, the size that the proffesionals play on, corresponds to a saving of as much as 88 tonnes of CO2e (CO2 equivalents). Since we recycle 100% of the product, this includes recycling of sand, rubber and mat.

As of today, we have the capacity to recycle 40 artificial turf pitches a year. This corresponds to 3520 tonnes of CO2e per year.

To give an idea of how much is saved, one can, for example, look at the reuse and material recycling of one large artificial turf pitch. Here you can help reduce CO2e emission equivalents to 10 times around the world with a petrol car, or the production of 820,000 new half-liter plastic bottles.

How expensive and comprehensive is it compared to today's alternative?

It is a lot cheaper to reuse and recycle.

It is generally half the price of buying a new one. Exact price, of course, depends somewhat on the transport of the materials.

Recycling still pays off. If you use recycled sand and rubber granules, the number of kilometers driven and the costs for both purchasing and transport will be significantly reduced.

How can climate savings from their services be included in circular and sustainability reports for the entire organization?

With a platform like the one Loopfront develops, municipalities and other owners of artificial turf pitches will easily be able to generate reports where both economic and CO2 equivalents are calculated. The two primary areas of focus should be; to reduce the use of transportation and the importance of actually buying recycled materials rather than acquiring new ones. Every year the pitches has to get filled up with new granules. It will be much easier to use recycled materials when you have a marketplace where you can get an overview of your own or others' holdings. This will also be able to appear in reports and make the savings that the organization achieves appearant.

Do you want to get started with reuse planning? Contact us!

Lars Solberg, TeBe Sport